Printing coasters - creating a difference for the brand

Printing coasters is no longer strange to restaurants, eateries, cafes, and coffee shops. Coasters today are made of many qualities such as absorbent paper, felt, plastic,... with many unique shapes. Coasters not only have the effect of promoting the store or restaurant by printing the brand name and logo, but also impressing customers with the attention to detail in every smallest detail. Join Artclick to learn about types of coaster printing with the article below.

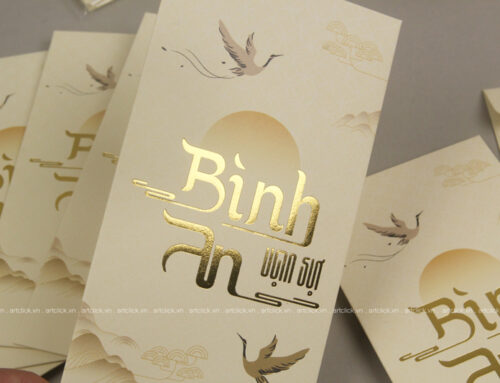

1. Print paper coasters

The paper used to make coasters is usually water-absorbent paper, covered in thick layers, and uses a specialized coating to allow the paper to evaporate before absorbing onto the table surface or making the paper soft. Businesses use printing brand logos on the surface of coasters to promote their brands to more users. Companies can also use coasters as giveaways during events.

2. Print embossed plastic coasters

This type of coaster is guaranteed to be waterproof and has a slightly raised edge to prevent water from spilling out. However, in cold, unventilated environments, water may still remain on the surface of the coaster. Advantages: easy to clean and compact, outstanding brand printing.

3. Print plastic coasters directly

This direct printing method is more cost-effective than the embossed printing introduced above.

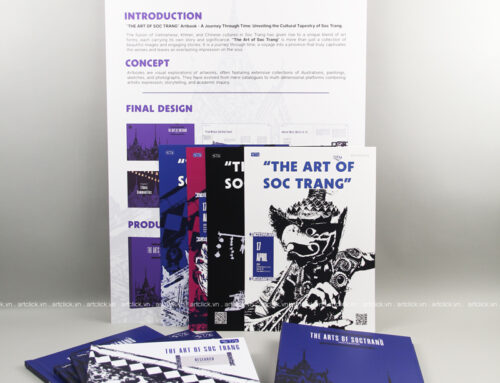

4. Print special shaped coasters

No longer are coasters required to be round, but coasters can now be printed with a variety of special shapes, as long as they can still fit the cup depending on the size.

5. Felt absorbent coasters

Felt fabric has been chosen by many people as coasters for a long time. For this material, the brand logo is delicately embroidered on the surface. However, this material is relatively difficult to dry compared to paper coasters. Therefore, it is easy to smell moldy or have stagnant water if not cleaned and dried properly.

6. Print wooden coasters

The market for printing wooden coasters is developing quite rapidly today, with the advantage of absorbing water and drying quickly, high aesthetics and elegance, however it is quite difficult to print the brand logo on top, making it heavier. compared to paper coasters and the price is relatively high.

(Credit: delotly.net)

7. Print square coasters

Square is also a popular shape when printing coasters. You can use many shapes to change, creating a new feeling for customers to use.

Printing coasters - creating a difference for the brand

Printing coasters is no longer strange to restaurants, eateries, cafes, and coffee shops. Coasters today are made of many qualities such as absorbent paper, felt, plastic,... with many unique shapes. Coasters not only have the effect of promoting the store or restaurant by printing the brand name and logo, but also impressing customers with the attention to detail in every smallest detail. Join Artclick to learn about types of coaster printing with the article below.

1. Print paper coasters

The paper used to make coasters is usually water-absorbent paper, covered in thick layers, and uses a specialized coating to allow the paper to evaporate before absorbing onto the table surface or making the paper soft. Businesses use printing brand logos on the surface of coasters to promote their brands to more users. Companies can also use coasters as giveaways during events.

2. Print embossed plastic coasters

This type of coaster is guaranteed to be waterproof and has a slightly raised edge to prevent water from spilling out. However, in cold, unventilated environments, water may still remain on the surface of the coaster. Advantages: easy to clean and compact, outstanding brand printing.

3. Print plastic coasters directly

This direct printing method is more cost-effective than the embossed printing introduced above.

4. Print special shaped coasters

No longer are coasters required to be round, but coasters can now be printed with a variety of special shapes, as long as they can still fit the cup depending on the size.

5. Felt absorbent coasters

Felt fabric has been chosen by many people as coasters for a long time. For this material, the brand logo is delicately embroidered on the surface. However, this material is relatively difficult to dry compared to paper coasters. Therefore, it is easy to smell moldy or have stagnant water if not cleaned and dried properly.

6. Print wooden coasters

The market for printing wooden coasters is developing quite rapidly today, with the advantage of absorbing water and drying quickly, high aesthetics and elegance, however it is quite difficult to print the brand logo on top, making it heavier. compared to paper coasters and the price is relatively high.

(Credit: delotly.net)

7. Print square coasters

Square is also a popular shape when printing coasters. You can use many shapes to change, creating a new feeling for customers to use.