Fast digital printing – Modern printing solutions today

Fast digital printing is one of the most modern printing methods, the birth of digital printing creates a new turning point in the global printing industry. This method is used by many countries, including Vietnam. So what is digital printing? What are the advantages and disadvantages of digital fast printing? Let's find out with Artclick's article below.

What is digital printing?

What is digital printing?

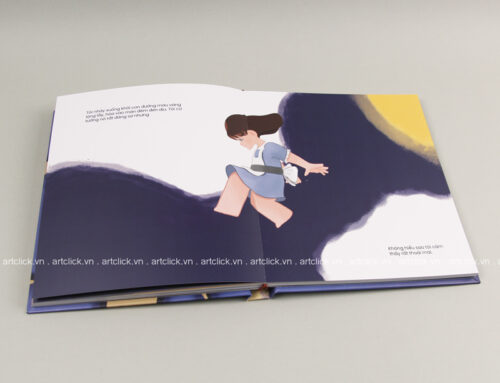

Digital printing is the most modern 2D printing method today, used to print images that require high resolution, sharpness, and speed. The printing process is done quickly by modern printers, without needing to go through manual steps. Fast digital printing is only suitable for printing products in small or moderate quantities with many different prints, while printing in large quantities has quite high printing costs.

What are the advantages of digital printing?

- Can print gradient colors: high accuracy, fast printing time, simple operation. Users can take pictures immediately without having to wait long

- Cheap when printing in small quantities

- Print many different images, or change the design if an error occurs

- Can print many sizes

- Can print on many types of materials

- Save labor, reduce product costs.

What are the disadvantages of digital printing?

- Large investment costs: The initial cost of machinery is quite large, it will be difficult to get your capital back if you do not carefully calculate the costs and operating profits.

- Not economical when printing in large quantities.

- Almost every printing option has advantages and disadvantages, the advantages of one technology are the disadvantages of another. You need to determine your purpose to choose the appropriate printing form.

Digital printing process in Ho Chi Minh City

Step 1: Prepare the print file.

After receiving the request or the design file is available, the designer will edit the file in terms of content, size, and color as required. Send the file to the customer for approval, then process the colors and export the print file.

Step 2: Process digital printing materials

Step 3: Proceed with quick digital printing

An intermediary software will be responsible for connecting the print files to the printer. Managers enter dimensions, adjust material positions, select print modes and print orders. The printing process is completely automatic.

Step 4: Post-print processing

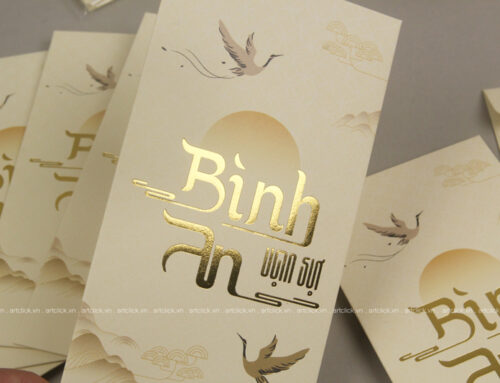

In order to eliminate unnecessary parts, complete the product, or other customer requirements such as stretch film, coating, die cutting, metal pressing, foil pressing, debossing, embossing, etc.

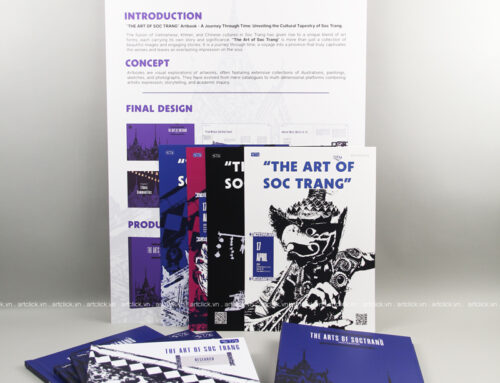

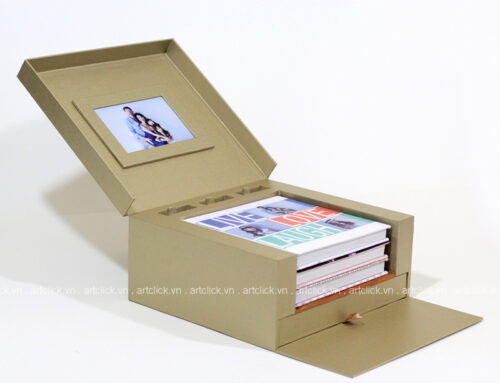

Application of digital printing

Compare digital and offset printing

The biggest difference between these two printing methods is the printing quantity

To put it simply, offset printing is like a giant photocopy machine that can print many identical copies in a short time. Digital printing is only suitable for multiple prints, running one copy at a time.

Offset printing uses a metal plate tube, engraves the image and transfers it onto a rubber tube before pressing it through paper or printing material, so the printing time is long, suitable for printing in large quantities, with uniform print quality. As for digital printing, printing on large paper sizes, printing many different copies in a short time.

Artclick – district 10 digital printing - is one of the pioneers in bringing to Vietnam the HP Indigo industrial fast printer - currently the pinnacle technology of industrial digital printers in the world for orders. Small and medium-sized goods require high quality, lots of variable information and short lead times.

Fast digital printing – Modern printing solutions today

Fast digital printing is one of the most modern printing methods, the birth of digital printing creates a new turning point in the global printing industry. This method is used by many countries, including Vietnam. So what is digital printing? What are the advantages and disadvantages of digital fast printing? Let's find out with Artclick's article below.

What is digital printing?

What is digital printing?

Digital printing is the most modern 2D printing method today, used to print images that require high resolution, sharpness, and speed. The printing process is done quickly by modern printers, without needing to go through manual steps. Fast digital printing is only suitable for printing products in small or moderate quantities with many different prints, while printing in large quantities has quite high printing costs.

What are the advantages of digital printing?

- Can print gradient colors: high accuracy, fast printing time, simple operation. Users can take pictures immediately without having to wait long

- Cheap when printing in small quantities

- Print many different images, or change the design if an error occurs

- Can print many sizes

- Can print on many types of materials

- Save labor, reduce product costs.

What are the disadvantages of digital printing?

- Large investment costs: The initial cost of machinery is quite large, it will be difficult to get your capital back if you do not carefully calculate the costs and operating profits.

- Not economical when printing in large quantities.

- Almost every printing option has advantages and disadvantages, the advantages of one technology are the disadvantages of another. You need to determine your purpose to choose the appropriate printing form.

Digital printing process in Ho Chi Minh City

Step 1: Prepare the print file.

After receiving the request or the design file is available, the designer will edit the file in terms of content, size, and color as required. Send the file to the customer for approval, then process the colors and export the print file.

Step 2: Process digital printing materials

Step 3: Proceed with quick digital printing

An intermediary software will be responsible for connecting the print files to the printer. Managers enter dimensions, adjust material positions, select print modes and print orders. The printing process is completely automatic.

Step 4: Post-print processing

In order to eliminate unnecessary parts, complete the product, or other customer requirements such as stretch film, coating, die cutting, metal pressing, foil pressing, debossing, embossing, etc.

Application of digital printing

Compare digital and offset printing

The biggest difference between these two printing methods is the printing quantity

To put it simply, offset printing is like a giant photocopy machine that can print many identical copies in a short time. Digital printing is only suitable for multiple prints, running one copy at a time.

Offset printing uses a metal plate tube, engraves the image and transfers it onto a rubber tube before pressing it through paper or printing material, so the printing time is long, suitable for printing in large quantities, with uniform print quality. As for digital printing, printing on large paper sizes, printing many different copies in a short time.

Artclick – district 10 digital printing - is one of the pioneers in bringing to Vietnam the HP Indigo industrial fast printer - currently the pinnacle technology of industrial digital printers in the world for orders. Small and medium-sized goods require high quality, lots of variable information and short lead times.